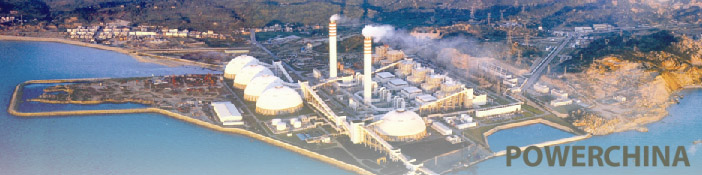

Fuzhou Kemen Thermal Power Plant of China Huadian Corporation(4×600MW)

By breaking through the traditional thinking on site selection, this power plant was constructed through massive mountain cutting, sea filling and backfill ground-making, and has successfully solved the following engineering difficulties: coastal mudflat with sludge thickness reaching 8-28 meters; backfill thickness reaching 7-13 meters; foundation treatment of site buildings. | Phase-II Project of Shenhua Funeng Hongshan Thermal Power Plant

Located in Yanqi Village, Kengyuan Town, Lianjiang County, Kemen Power Plant is situated in Kemen Port Economic Development Zone on the southern coast of Luoyuan Bay. Two 600MW supercritical coal-fired generator sets involved in Unit 1# Phase-I Project have been put into production in August 2006 and December 2006 respectively, while two other similar generator sets involved in Unit 1# Phase-II Project have also been put into production in August 2008 and November 2008. Kemen Power Plant is not only an important power supply source in Fujian Province, but also a critical power plant of East China Power Grid. The power generation unit adopted the home-made 600MW supercritical coal-fired generating unit introduced by Shanghai Electric Group Co., Ltd, and the limestone-gypsum wet FGD facility was constructed simultaneously, while the conditions for constructing denitration facility has also be reserved. Besides being one of the first domestic 600MW supercritical power plants, it is also the first 600MW supercritical power plant constructed by Huadian Group after its establishment. With Unit No.1 and Unit No. 2 having been put into operation in August 2006 and December 2006 respectively, this power plant is known as the most profitable power plant among similar projects of Huadian Group and the demonstration project inside the Group. Great progresses have been made in areas of site selection, backfill ground-making, explosive replacement, and the development & application of PDMS 3D integrative facility system and design cycle management platform(3DWEB). This project was granted the "First Prize for National Excellent Power Sector Design" in 2007. | Phase - I Project of Guodian Fujian Nanpu Pouer - Plant (2 ×300MW)

With planned capacity of Guodian Fujian Nanpu Power Plant reaching 1800MW(first-phase projecting being 2×300MW), the three coal-fired generating units were produced and supplied by Harbin Electric Machinery Co., Ltd, Harbin Turbine Company Ltd and Harbin Harbin Boiler Co., Ltd, and the limestone-gypsum wet FGD facility was constructed simultaneously. The project kicked off on February , 2004, and Unit No.1 and Unit No.2 have been put into operation on November 24, 2005 and April 10, 2006 respectively through "168h". This project has been granted the first prize for excellent engineering design of Fujian Province. | Xiamen Songyu Power Plant(4×300MW)

Songyu Power Plant Phase-I Project of Xiamen Huaxia Electric Power Company, with home-made 300MW subcritical coal-fired generator sets introduced from Shanghai Electric Group Company Limited for all the three main units and jointly designed by FEDI and East China Electric Power Design Institute. The project was completed and launched into production in 1996. Home-made 300MW subcritical coal-fired generator sets were introduced from Shanghai Electric Group Company Limited for all the three main units of Xiamen Songyu Power Plant Phase-II Project of Xiamen Huaxia Electric Power Company. The construction of seawater boiler-tail flue gas desulphurization facilities and SCR flue gas denitrification facilities was synchronized with the construction of Phase-II Project. Meanwhile, Phase-I Project was supplemented with seawater flue gas desulphurization facilities and SCR flue gas denitrification facilities. It is the first power plant (of the same type) to carry out simultaneous construction of seawater flue gas desulphurization facilities and SCR flue gas denitrification facilities in China. Its No. 3 unit even broke the national record with its 300MW coal-fired unit being built and put into production in just 18 months. The project won the second prize for Fujian Provincial Excellent Project Design. | Fujian Longyan Kenkou Thermal Power Plant(4×135MW + 2×300MW)

The 4×135MW CFB (circulating fluid bed) boiler coal-fired units were built for the Phase-I Project of Longyan Kengkou Thermal Power Plant of Fujian Longyan Power Generation Co., Ltd. The project won the first prize for Fujian Provincial Excellent Engineering Design and the first prize for Fujian Excellent Engineering Survey. The 2×300MW CFB boiler coal-fired units were built for the Phase-II and put into operation in 2010. | Integrated Gasification Combined Cycle(IGCC)Project of Fujian Refining & Ethylene Project

FREP COGEN project indicates the steam and electric power production area for the extension project of Fujian Oil Refinery. The COGEN unit, the partial oxidation device and the air separation device constitute the IGCC system. GE9E combustion turbine is used as the gas turbine. The project features sophisticated technique, cross-industry, etc. It is the first time that FEDI has taken part in a power generation design project for refinery industry, which provides a precious experience for our future participation in the design of IGCC projects. | Phase-I Project of Huaneng Fuzhou Power Plant(2×350MW)

This project was jointly designed by FEDI and East China Electric Power Design Institute. With subcritical units imported in a complete set from Mitsubishi Company of Japan, the project has an installed capacity of 2×350MW, and was completed and launched into production on 26 December 1988. The rock and soil reconnaissance survey project independently completed by FEDI won the silver award for National Engineering Survey in 1993. | Phase-I Project of Zhangzhou Houshi Power Plant(2×600MW)

During its cooperation with Southwest Electric Power Design Institute in undertaking the survey and design of Phase-I Project of Zhangzhou Houshi Power Plant, FEDI independently undertook the survey and design of the coal transmitting system, the water purifying station, the ash field and some auxiliary systems. For the first time in China, a complete shut-off coal yard in round shape with a diameter of 120 meters was used in the technological design of a coal transmitting system. Its coal transmitting system consists of 54 belt conveyers, among which the high-capacity belt conveyers with high parameters are used from the wharf to the coal yard to constitute one of the largest coal transmitting systems in China. The project won the silver medal for national engineering survey. | Phase-III Project of Shaowu Power Plant(2×660MW)

Fujian Huadian Shaowu Power Plant is located in Nanping, Fujian, with current installed capacity being 2×125MW. The Phase-III project will involve 2×660MW home-made ultra-supercritical coal-fired units, with plant area adopting triserial layout (Garret-type layout in vertical direction). High-efficient emission control facilities will be constructed at the same time, so as to keep the discharge concentration under the emission limits for gas-fired turbines. | |

|